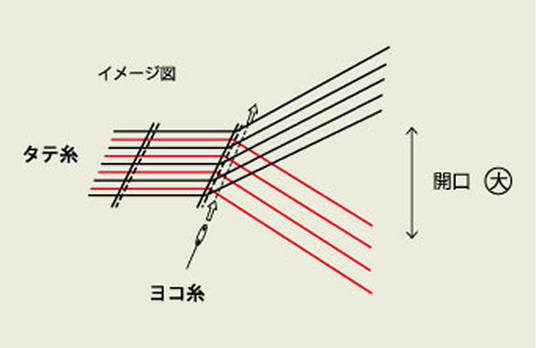

Old-fashioned loom = slow weaving

Because the opening size can be made larger, the warp threads can be pulled with weak tension (without putting too much strain on the threads) and woven slowly. This allows the original characteristics of the threads to be more easily expressed on the surface of the fabric.

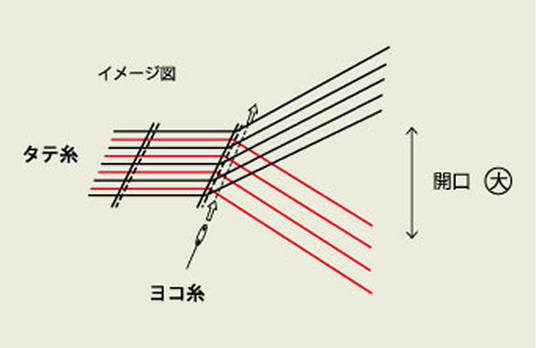

Latest loom = faster weaving

In order to increase the speed at which the warp threads move up and down, the opening is made smaller, and the warp threads are pulled tighter. This tends to make the fabric smooth.

-

Binder print processing

-

Changes in rubber print

Parts

Buttons, rivets, zippers, etc. These small supporting features make their presence known in simple designs.

At UES, we carefully select even the smallest parts. There are many original buttons and rivets. Don't miss them.