Strong! UES socks

Although traditional, UES socks are highly rated for their comfort and durability.

We will tell you the secret behind its strength that makes it so hard to break.

1. Thick thread

While regular socks use threads that are thick, but equivalent to #10 single threads, rags use threads that are almost twice as thick as #5 single threads. The thickness of the thread directly translates into high durability. We order this thick thread for rags. Also, by using natural uneven threads, a natural uneven texture is created on the surface, which also contributes to the texture of the product as a simple item.

*10/1 100% cotton and 10/1 50% cotton acrylic are yarns commonly used for socks.

*Heather yarn and unbleached yarn are the yarns used at UES.

*As you can see from the graph, the yarn used in UES, which is equivalent to No. 5 single yarn, is about 2 to 3 times stronger than basic sock yarn.

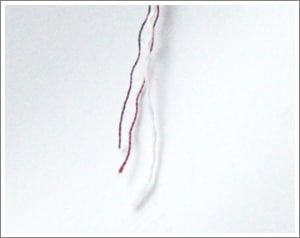

2. 3 strands twisted

During the spinning process, fibers are twisted together to make thread. The resulting thread is then twisted together in three strands to create Mikoyori. Most regular socks are made with one strand (single thread) or two strands (futako). Wes socks have three strands twisted together to give them extra strength.

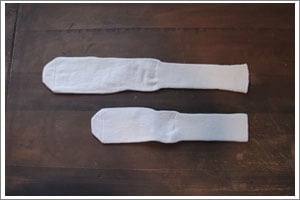

3. Tighten the stitches

If the stitches are coarse, when force is applied, the stitches can be pushed apart by the toenails, etc., and the yarn can easily wear out. We knit our rag socks using a low-gauge double cylinder knitting machine with 102 needles. As shown in the reference photo, we use a manufacturing method in which the socks are knitted large and then shrunk small in post-processing. The resulting socks are thick and durable with a tightly packed mesh.

4. Careful selection of ingredients

For example, the elastic cuff (the stretch rib where the legs go in) is made with a double layer of polyurethane, which is less likely to become brittle. Many of the cheaper ones use natural rubber to keep costs down, but this has the disadvantage of being easily brittle.

Wet socks are made from high-quality materials, so they fit well and last a long time.

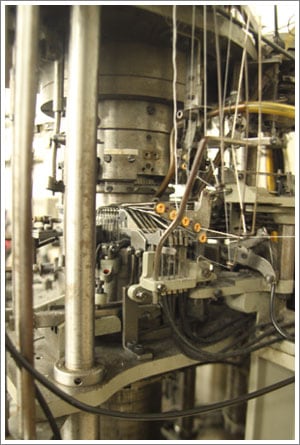

5. It must be made in Japan

Wes socks are made in Japan. There are many benefits to making them domestically, including in terms of quality control. The brand's desire to make strong socks reaches the craftsmen. Socks are made using machines, but as it is humans who adjust the machines, it is important to understand the direction of the product when creating the product. We understand the tension of the thread and the quirks of the machine to devise ways to create strong socks.

6. Customer feedback

Irregular yarn 3-ply socks

They are very durable and comfortable to wear. When I wear boots, regular socks tend to slip down, but these socks don't. They come in a wide variety of colors, and I currently have six pairs. They are very useful.

The fabric is strong and thick, so it has good cushioning and I wear it when wearing boots.

The fabric is sturdy and goes well with boots! The logo on the toe is cute. I'm totally hooked.

We use Wes socks in many colors. They are so comfortable to wear that even if they tear, you can just sew them back on. We have almost every color available. I highly recommend these socks!

I was worried about using it in the summer because the fabric is thick, but it doesn't get stuffy and I now only need UES socks.

This is my first time purchasing these, but they are thick and comfortable to wear, and don't feel too tight.

It is thick and fluffy and feels very comfortable.

Please try it first.

To purchase, please visit the socks page.